Automation Is Engineering the Jobs Out of Power Plants

As coal-fired electric power plants close across the U.S., they take with them coal mining jobs, to be sure. And while those job losses have generated considerable political heat, a no-less important employment shift is under way within power plants themselves.

Gone are many of the mechanics, millwrights, and welders who once held high paying jobs to keep coal-fired power plants operating.

As maintenance-intensive coal-fired power plants—chock full of rotating equipment and leak-prone pipes and valves, not to mention conveyer belts and coal ash handling equipment—are retired they are being replaced to a large extent by gas-fired units that make full use of sensors, predictive maintenance software, and automated control systems.

As a result, the extensive use of analytics and automation within natural gas-fired power plants means that staffing levels can be cut to a fraction of what they were a decade ago.

Recent announcements confirm the trend.

On August 1, Michigan-based DTE Energy revealed plans to spend almost $1 billion to build a 1,100-megawatt gas-fired power plant. When the station enters service in 2022, it will replace three existing coal-fired units that currently employ more than 500 people. Job openings at the new gas-fired plant? Thirty-five full-time employees, says a DTE spokesperson.

In late June, Louisiana regulators approved a plan by New Orleans-based Entergy Corp. to build a 994-MW gas-fired combined cycle power plant. The $872 million plant and associated transmission assets are slated to enter service in 2020. Job openings when it comes on line? No more than 31 people to manage, operate, and maintain the plant.

The lower headcount required at new gas-fired power plants like those in Michigan and Louisiana is the result of automation and advances in control system technology.

“What changed is the evolution of technology,” says W. Dale Claudel, vice president of power generation for Entergy.

Entergy’s plant in Lake Charles, La. will use two Mitsubishi 501G air-cooled gas turbines coupled with a Toshiba steam turbine. Claudel says that a single control room operator will be able to launch the plant’s entire startup procedure with the proverbial push of a button.

Once switched on, the plant’s automated systems are designed to synchronize generator functions, set ramp unit output, monitor firing temperatures, measure and adjust air emissions, all functions that previously required human oversight or intervention.

(Entergy Louisiana has a relatively small amount of coal-fired generation that will continue operating even after the Lake Charles unit is built.)

What’s more, in a conventional power plant outfitted with a boiler, multiple field operators would trek into the plant to visually inspect equipment and burners that were installed on multiple levels of the structure to ensure they were ready for firing. With the new plant, Claudel says that automation will monitor the combustion process, eliminating the need for many of the field operators required to walk the plant prior to startup.

A recent benchmarking effort by Black & Veatch used data from a commercial database of North American gas-fired power generating plants to offer insight into how gas-fired power plants are staffed.

Phillip L. Webster, P.E., associate vice president and project manager of Energy, Power Generation Services at B&V says that the firm’s research shows that a gas-fired combined-cycle power plant with a 565-MW generating capacity needs around 27 full-time personnel. A plant configured to yield nearly 300 MW more generating capacity requires only six additional people.

So even though the second gas-fired unit is more than 50 percent larger than the first in terms of generating capacity, the number of employees needed to run the plant is only around 25 percent more.

“The roles just don’t need to exist,” he says.

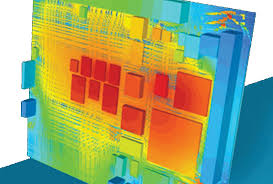

One big reason is that new gas-fired power plants are equipped with sensors that provide constant data streams that are used to monitor turbine performance and feed predictive maintenance algorithms. Predictive maintenance means that maintenance outages can be scheduled well in advance of an equipment failure, and reduce almost to zero the need for in-house maintenance staff.

Software “minimizes the effort of the operations and maintenance team,” says Shin Gomi, a marketing vice president with Mitsubishi Hitachi Power Systems Americas. The operational reliability of an advanced gas turbine may approach 99 percent, he says, and operating efficiencies are edging toward 65 percent, nearly double the efficiency of most coal-fired units that are being replaced. Expenses for operations and maintenance, fuel, and employees all can be cut with gas-fired power plant technology.

With gas price volatility greatly reduced and gas supply greatly enhanced through hydraulic fracturing technology, long-lived gas-fired technology can be planned for by cost-sensitive utilities that historically have limited options available to them to enhance shareholder value.

The extent of automation and digital equipment in new gas-fired power plants also means that operators need to have different sets of skills. Gone are the specialized millwrights and boiler operators.

They are being replaced, Entergy’s Claudel says, by people who “understand operations as processes” and who are able program, troubleshoot, and tune the ultra-efficient turbines.

No Comments